If I get one more client who sends me die-cut art with no bleed and tells me I don’t need it because I’m just cutting off the white part, I think I’m gonna quit.

Die cut art NEEDS BLEED.

/RANT

If I get one more client who sends me die-cut art with no bleed and tells me I don’t need it because I’m just cutting off the white part, I think I’m gonna quit.

Die cut art NEEDS BLEED.

/RANT

The seemingly endless parade of people engaged in paid graphic design work with little or no understanding of what they’re doing never ceases to baffle me.

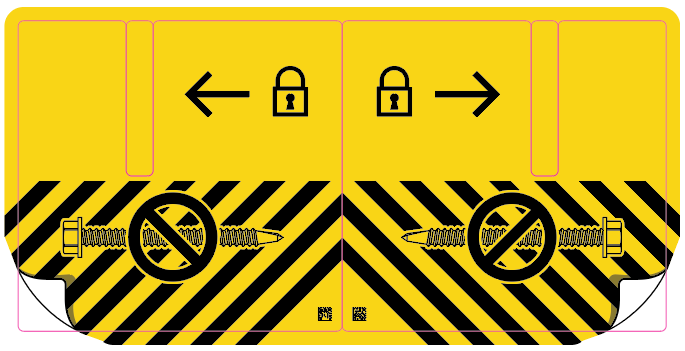

Coincidentally, I spent the better part of a morning this week explaining to a design degree holder why to get these labels produced:

we submit this:

I work sometimes with different organization’s in-house designers as part of my day job. Two or three months ago, I received supposedly final artwork from one of them with no bleeds.

When I asked her about it, she believed that bleeds were holdover practices of older designers who hadn’t gotten used to digital technology. She went on to say that bleeds obviously made no sense since the printer just cut them off and threw them away anyway.

She was the employee of a client, so I needed to be diplomatic in how I responded, but she had apparently been producing artwork like this for the entire two years since she had graduated from some for-profit, online design school.

Why we don’t have minimum competency and licensing requirements in this field, like most other professions have, is a mystery, which brings me to the verge of a rant that I’ll keep inside for now.

Just my curiosity…Do you all find that the bleed issue is more current. I was a CSR for a nationwide Forms manufacturing company for 16 years during the late late 80’ through the early 2000’s. On the manufacturing side as CSR’s we all new bleeds where one of the most important questions to ask about due to press limitations regarding grippers and lock-up. I found most of the people (mostly brokers) were extremely knowledgeable about it and seldom had issues. Seems after reading on here it’s a more recent trend to not understand bleeds. I have a long time friend and designer buddy. Who i was buying my business cards through when I was doing wedding work. I designed them though and he would always comment to the fact that “I don’t believe you actually include the bleeds in your files” This has been more recent though.

Bleeds, resolution issues, copyright infringements, dot gain, color gamuts, you name it — I just think there are a whole lot of half-baked, overconfident newbies out there who haven’t learned the ropes before jumping into things they don’t know about.

^^^^^ THIS!

I am still amazed at how many are under the delusion that changing something 10% negates the copyright. The myth that just will not die

So many seem ill equipped to take on the profession they are supposedly trained for.

The problem is they are not trained. Aside from the ones “learning” from watching youtube videos, the ones that go to college are just not taught print production. They make pretty pictures, they ‘push the envelope,’ their professors gush about how this or that layout is new and revolutionary, but I really think a lot of design education is the blind leading the blind. We are that far into the digital design future that many of the teachers have never done print production work at all.

Like B mentioned above, they think old practices are “archaic” but don’t understand they are still done for a reason.

Next time I have some free time, I might do a photo study of what happens when you don’t put bleed on a die-cut. And by die cut I mean the new, revolutionary concept of cutting without dies using table CNC machines.

Had to explain Bleed for the last time - now I keep this and copy + paste it, amending as appropriate.

As with any print job, if anything on the page goes up to the edge, it must go over the edge (bleed off). This is for several reasons:

even with the best guillotine it is impossible to cut a stack of paper to an exact size with zero tolerance

it is impossible to print exactly in the same place on every sheet of paper and printing on both sides of the sheet just multiplies this problem

it is impossible to collate several sheets into a set with total accuracy and a booklet is collated and folded sheets which makes things less accurate

with a booklet it is folded and stitched first, then guillotined to size which makes everything even less accurate

We could cut the pages a bit smaller but your text is too close to the edge anyway. It is normal for any print job to have bleed and it is even more necessary with a booklet.

Feel free to use this in any way that helps.

Ha ha…double-sided die cut…

I have enough trouble explaining to them why they need to make 2 files, one for front and one for back. Bleeds are secondary issues with those.

I often get things like Standees where they tell me to “just reverse the other side.”

Ok. I can do that… but the number on the guys jersey and the type on the sign he’s holding, are all going to be reversed.

Willy, it’s been a slowly snowballing thing for the past decade, but even more recently has been the argument coming back at me that they are “not needed.” I don’t know where that information is coming from. Probably some youtube video.

I have yet to encounter this thankfully but I believe those clients are out there.

During the paste-up era, designers needed to understand the processes in order to build the mechanicals. Even15 years ago, which was well into the digital era, most senior designers and design professors learned the trade in the paste-up era and were able to pass along some of the essentials to their juniors and students.

Today, as you mentioned, we’re a couple of generations into it, and, in many instances, we’re to the point of “the blind leading the blind.” If something looks nice on the computer monitor, it’s good to go. If it prints from their desktop printer, it’s ready to save into a PDF and emailed to the printing company.

If I could make changes to how our system churns out new graphic designers. it would be the following.

If this sounds tough, that’s the whole point, but it’s not dissimilar to the routine that nearly every other profession requires except design.

Good advice, StudioMonkey. If there’s one thing I’d add to your list it would be something about safeties since they’re closely related and the logic for both is the same.

If the bleed is 3mm and the trim is, say, a couple of millimeters off and cutting into the bleed in one direction, the trim will be off an equivalent amount on the other side and cutting into the safety margin.

I can hear millennial heads popping, reading that B.

They’re all saying “That’s not fair. You can say that cuz you been doing it 20 years. How’s someone just starting out supposed to do all that? It would take YEARS!”

Which is the point.

It takes 3-5 years just to become a journeyman electrician and another 3-5 years for a journeyman to become a master. There’s a reason for that. Hours and hours of skilled practice are required.