11+ years as a graphic designer and I’ve always created CMYK for Print and RGB for Web…however I was noticing that everyone I came across on YouTube (regarding Etsy) saves their print designs as RGB before zipping them up and placing them on their Etsy account for purchase. I was confused by this. Then I found a video from Printful (a printer) that said it’s best to send in an RGB file because (as we know) it has the best color range and that a printer will always convert it to CMYK and ‘match’ the colors as best as they can to look more like the RGB file sent in. I also read where someone did a test and had a CMYK printed and an RGB converted to CMYK at the printer printed and the RGB looked best. Is everyone doing this now? Is this the best practice, or too much of a RISK? Just wondering what you all do or think about this. Thanks!

It’s been a long time like this.

Converting to CMYK used to be a necessity, but now it depends on a number of variables.

For digital printing, RGB is usually best because most digital printers use six or more colors of ink, so the color gamut is larger than with only CMYK. Because of this, letting the printer RIP make the conversion to however many colors their printers handle is usually best.

For offset CMYK work, it gets more problematic. Yes, many offset RIPs will convert the RGB on the fly to CMYK, but doing so takes away your ability to make sure the CMYK conversion is what you want. For example, if you send an RBG file with black text, the RIP will convert the RGB to a rich CMYK black instead of 100%K. On the other hand, if you send a CMYK Illustrator file with 100%K text but with placed RGB photos, the RIP will keep the text 100%K while converting the photos to CMYK on the fly.

I still prefer to do the RGB to CMYK conversions myself when I’m in doubt. Part of the reason is that I’ve done it that way for years and don’t quite trust changing the routine unless I’m sure the printing company can handle it. When I asked various printers about it, I’ve gotten different responses. Many offset printers I work with have told me they don’t want RGB files.

All too often, clients think they can save a few dollars by lining up the printers themselves. They typically don’t know one printer from the next and underestimate their ignorance, but when they insist, I send them only CMYK files since any printer (including digital printers) can handle them.

And speaking of ignorance, there are people here more deeply involved in actual printing than me, so you’ll likely see a few people disagreeing with me or providing details that I don’t have.

Just to expand on what B has said.

If you have images from different sources - like RGB from stocksites, for example.

You would in the past go into photoshop and convert this RGB image to CMYK.

However, Adobe and other apps can do this same conversion on the fly from the PDF conversion - and it’s the same conversion that Photoshop or similar apps would give you from CMYK to RGB.

The days of holding a RGB image for the web, a CMYK version for print etc. are long gone.

Use the same source file across many different devices.

This is simply because you don’t get any gains - unless you’re specifically being controlling of the CMYK output.

For example, for a art gallery.

When you convert RGB to CMYK - CMYK has many different outputs - digital, litho, etc. and many different Colour Profiles, US Web Offset - Euroscale Coated, Uncoated

All each changing the colour the fit that profile and suit that printing method.

You’re best advantage is to leave all your colours as RGB, sRGB, Pantone, CMYK (from any source)

Place these in your files

When exporting to PDF for print - use PDFX4a - which retains the colour - it does no conversion.

RIPs often come with built-in color management tools, including the color lookup tables (LUTs), to ensure accurate color reproduction on different types of printers.

When I deal with amateurs or amateurish software when it comes to print I provide sRGB.

A lot of office printers expect RGB and don’t leave CMYK alone so you e.g. don’t get 100% K Text anyway. I struggled to get MS Word to print CMYK properly and failed.

When I deal with pros I provide CMYK or combined CMYK and RGB. RGB solo I’d only provide for textless images for printers with wider gamut.

For 90% of my work, I still convert to CMYK. I do a lot of illustrated trade titles (coffee table books with strong, rich imagery). Many are books with of artworks and objet d’art that need to either be colour accurate, or that I need to control the colour of, based on a number of factors.

For example, one author who I work with always wants the colours as rich as possible, but his books are printed on uncoated stock. I will, of course do the initial colour correction in rgb, but once converted, I often need to make further tweaks in the CMYK.

These are always printed offset, as they are printed in the tens or hundreds of thousands and the entire workflow uses a profile supplied by the publisher, determined by the stock used.

The final artwork then goes to the publisher’s production department. They won’t make any further amends, but will check it over for any production issues.

They will then determine which of their printers they use. It is sent to one of a few, who could be in China, Vietnam, or Italy. (A lot is determined by the content, as China refuses to print certain books – for example there can never be mention of Taiwan as a separate state.)

I have no control over this – I’m not going to Shanghai to do a press pass (though I could be persuaded to do a weekend in Bologna!).

Because of this, I need to know, with as small a margin of error as possible, that what I expect to come back, does.

Furthermore, they are always printed with text as an overprinting 5th black, for foreign language Co-Ed’s, so I have to know that when the artwork goes out the door it is correct.

In short, as others have said, it all depends on the job you are doing. The trick is to always ask the printer printing the job how they want it supplied.

Yes, that’s another reason why I prefer to make the RGB to CMYK conversions myself on non-digital jobs. I don’t want any surprises.

For example, I might have a nice landscape photo in a prominent spot in a magazine. Once converted to CMYK, I find the beautiful, rich RGB blue sky turns into a dull bluish-grey. Once I know this, I might be able to boost the cyan or increase the saturation or vibrancy of the sky to help mitigate the problem.

It may have been mentioned somewhere above that once you convert an image to CMYK (or any other smaller gamut) and save it, all of that RGB color data is lost. You cannot recover it by converting the CMYK image back to RGB.

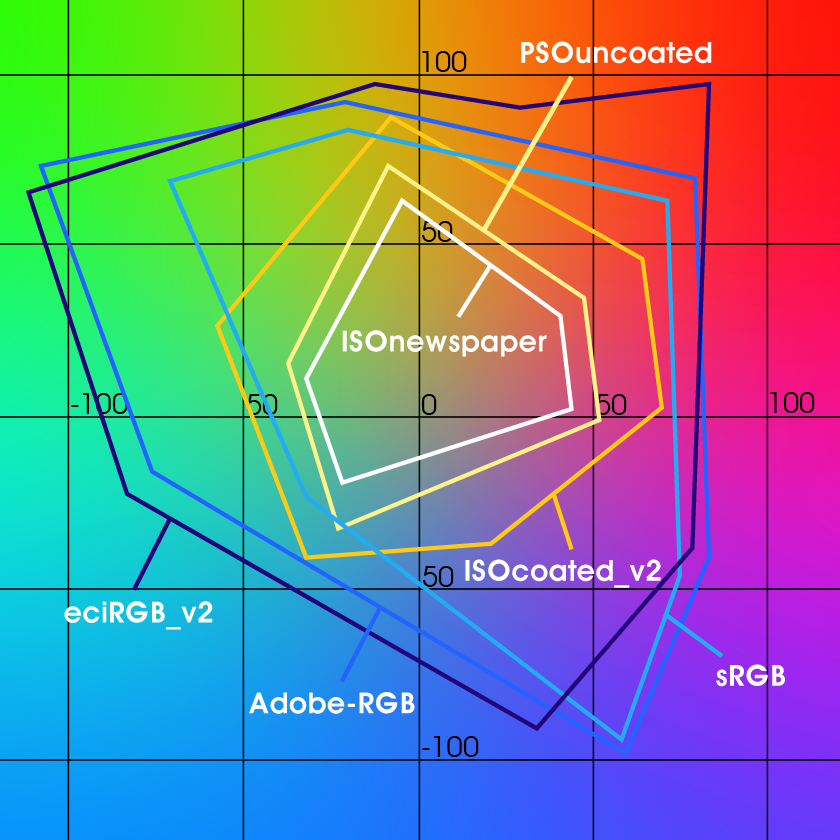

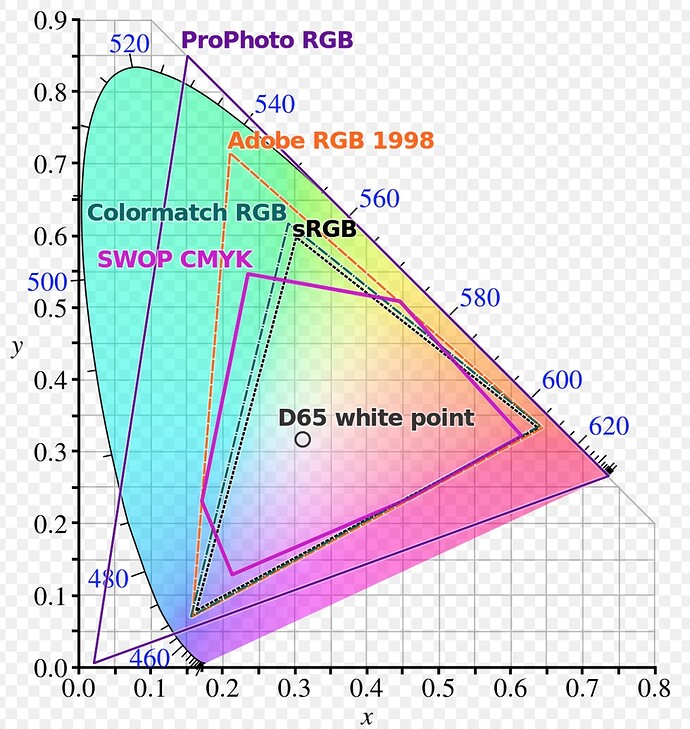

Also as Joe was pointing out gamuts above, I wanted to point out that sRGB is not not better than CMYK, and in some cases detrimental. See the gamut chart below and how much larger the CMYK gamut is on the blue-green side compared to sRGB. If you can get stock photos in Adobe RGB do it. Avoid sRGB. And if taking your own photos, of course use RAW.

Thank you all for your input, it’s much appreciated! All being said, I went ahead and sent a friend an RGB file to print an 8x10 and she printed it through CVS Pharmacy. It was horrific! The white wood had a blue tint and the blue flowers were intensified x10! So I decided to print her a CMYK version at Walgreens. Come to find out they don’t accept CMYK! So I sent them the RGB file and they actually did a nice job with the print. As mentioned it seems to be a hit or miss. Regarding Etsy, someone suggested that I offer both JPG RGB and PDF CMYK versions of the artwork so they can pick and choose. Sounds like a lot of work, but I don’t want to risk them getting a bad print (although it sounds like that’s on the printer they go with.) Thanks again everyone!

Graphic designers must comprehend the distinction between CMYK and RGB colour modes and how they relate to various printing techniques. Since CMYK is created explicitly for four-colour printing and can faithfully reproduce different colours on printed goods, it is typically the chosen colour mode for print jobs. On the other hand, the ideal colour mode for digital projects and screen-based designs is RGB, which employs a broader colour spectrum better suited for display on electronic devices. Yet, the method for choosing between CMYK and RGB for print projects can change based on the printing technique and the printer utilized.

Wow that reads like ChatGPT…

“digital projects” is amorphous. All the printing I do is done ‘digitally’ (No plates involved. It’s all digital data sent to a Rip.)

To add to PrintDriver’s bit there - any modern RIP worth a damn will handle RGB input just fine, no matter what the output device is.

The whole notion of ‘must design in CMYK for printed stuff’ is as antiquated as the notion that all output files bound for digital printing must be EPS files.

That’s not to say that you shouldn’t be aware of the differences and limitations though.

I wish they had discontinued .eps when they introduced transparency. EPS files are the bane of my existence, well one of many.

When I took a job with my current employer 8 years ago in the prepress department, EPS was the standard output format. It took me almost 3.5 years to convince/prove to them that PDF was better. They just had to use it right.

But they’d gotten bit one too many times by using it wrong that they just sorta gave up on it. We’ve been EPS free for years now though.

Now, if only I could get our smaller division to stop using PDF as the working/mechanical file and the output format.

There are plenty of times where I have needed to control/adjust the CMYK breakdown (adjusting density of blacks, for example), where leaving it to mechanical conversion would render this impossible.

Where it comes to stock images - or images supplied from digital cameras/phone cameras - converting and colour correcting is a bit overkill.

export to pdf and colour conversion does the exact same conversion as you would if you did the colour conversion in Photoshop.

You can of course colour correct if you convert in CMYK.

But the only time I’ve had to do this in 25 years is for very high end books, like art gallery, etc.

We used to produce the largest holiday destination catalog. For holiday goers going abroad. Remember those things! You’d go into a travel agent and pick up their catalogs, pick a holiday destination etc.

Well each of those photos were actual photos (no digital then) and each photo had to be scanned on a drum scanner and colour corrected and then inserted to the layout. I was the designated drum scanner operator and colour corrector - and I’d line up all the images on the drum and scan and the only option was RGB.

The images would be colour corrected in RGB (as the monitor was RGB) it was an old cathode ray tube monitor, not the fancy ones you have today.

I had a hood around the monitor with controlled lighting.

And the level of detail that went into colour correcting was astronomical - and then for key images - there were photo touchups that you wouldn’t belive - the guys doing the touchups and further colour corrections were insane at what they did.

I learned a lot from that process.

But most of the colour correcting was done in RGB - and then converted to CMYK in photoshop - and maybe a slight adjustment after some chromolain proofs - but that was rare.

Our digital print processes never require an prepress ‘artist’ to adjust the channel breakdowns, unless they’re doing some kind of ‘by-eye’ color adjustment to appease a customer. That mostly went out the window years ago. We routinely request color samples from customers who require a good match and match to that sample with a named custom spot color(s).

The RIP handles all the black point / white point / conversions via the icc profiles and color management settings. Any one of our fleet of digital presses is rarely off more than 2dE00 from any other press in the fleet.

I can see that kind of adjustment being a more normal thing for more conventional print technologies though. I thank my lucky stars every day we don’t do 4-color process screen print, etc.

I’ve recently had printers asking me for files in RGB (I’ve always known it to be CMYK in the past)

Personally I find the idea of supplying print files in RGB more confusing… it sounds good in theory, e.g. ‘no more dull CMYK colours’ but now I’m even more confused about how the colours will turn out when printed.

Like I can’t pick a really bright green and then expect it to come out in print just because the printer wants an RGB file ![]()

That’s not the theory or the purpose behind supplying RGB instead of CMYK. RGB is an additive color space that can’t be printed. Printing requires a subtractive color space, so the RGB files must be converted to some variation of CMYK in all printing situations.

The purpose behind sending RGB files to a printer is to let the printers do the conversions for you in ways that best accommodate their output devices and printing processes.

For example, digital printers typically use more than cyan, magenta, yellow, and black. In addition to those inks or toner colors, digital printing devices might have an additional extra-vivid cyan or magenta (or more) that enables the printed output to better match the colors in RGB files. In those cases, it’s best to let the printing machines convert the RGB file to whatever color separations they need to take advantage of the larger color gamut they can print.

Four-color offset printing still uses straight CMYK. However, letting the printing company do the conversion is often better because their output software might be better adjusted to make the RGB-to-CMYK conversion for their printing presses. Most modern printer RIPs are fully capable of converting RGB to CMYK separations on the fly.

With these things being the case, it’s often not necessary for you to send CMYK files since the printing company might be able to make the conversion from RGB.

However…

For various reasons, some printing companies still prefer getting CMYK files. I regularly work with some that still request them.

In addition, you might want to know how that “bright green” you mentioned in your question will look when converted to CMYK before sending it off to an offset litho printer. If that green looks too dull in CMYK, you might be able to boost the vibrancy or saturation or fine-tune the color balances of the green to better achieve what you want than if you sent the RGB file to the printer and had them do it.

Summing up, there is no universal right or wrong way to handle this problem; it depends on the situation. If the printer requests CMYK, send them CMYK. If the printer requests RGB, send them RGB. If you send files to a client where they will line up the printer, you might want to send them CMYK to be safe.

In general, I still make the RGB-to-CMYK conversions myself when sending work to offset printers unless they tell me to do otherwise. In general, I send RGB files to digital printers since they’ll probably be using printing machines that can print a wider color gamut than straight CMYK, so it’s best to let them make the conversation from RGB to CMYK+.