Part of my job includes being art director for a magazine. The magazine is 48 pages, saddle stitched. The printer is chosen by bid so I have little control over that. The last issue didn’t come back as I expected. The interior pages are slightly larger than the cover. We asked the printer about it and they said it was due to “page growth.” I’ve never heard of or experienced page growth. We’ve used this printer before and this wasn’t an issue. Page growth is not the same thing as creep. The printer said that the pages physically grow. They didn’t appreciate it when I asked if the pages were full grown. Has anyone else experienced page growth?

They didn’t even crack a slight smile?

I’ve never heard of pages growing larger after they’re printed and trimmed. What are they attributing it to, humidity changes or the paper pulp coming from not fully grown trees?

Sounds like an excuse to me for sloppy work. Whatever caused the growth spurt, they’re responsible for it.

Is the magazine self-covered or is it on a different, heavier stock? If it’s self-covered, why didn’t the cover grow as much as the inside pages?

I’m guessing that the cover is a coated stock and the inside pages are uncoated. I haven’t seen it happen but I can imagine it. I know that in humidity the printers have a fine old time trying to get paper to stay the same through each pass. We called that paper stretch though. I wonder if it’s anything like paper growth?

I guess the next thing to ask the printers is that if there is a stock that has less growth that they can recommend because the current stock is obviously not good enough!

Who knows, maybe they are using a dud cheapo stock that is known to do this. And they’ll change it only when called out.

Sounds like an excuse to me too. I’ve never heard this happen in two decades of my publishing experience. They either under-trimmed the paper or over-trimmed the cover.

Try putting the books in a drying cabinet for a day or so. Do the pages shrink again?

If so then its cheaper uncoated paper absorbing more moisture from the air, resulting in a larger expansion in size than that of the (presumably) coated cover stock.

If not then he’s blowing smoke up your a$$ and the pages should have been trimmed to size.

Creep? Sounds like sloppy finishing to me. You said the printer is selected by bid, maybe you just got what you paid for.

^ This. I’ve never heard of ‘page growth’. Poppy…cough…cough

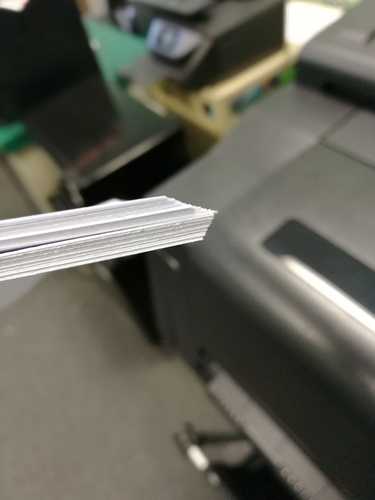

The issue is called “creep” (or growth I suppose) and they are not making it up exactly. Take any small stack of papers, IE your 12 sheets for your 48 page book, and fold them in half. you’ll notice the paper closer to middle peak out from the cover.

These pages have a shorter distance to travel since they are closer to the center of the fold point. outside pages must wrap around the interior pages and therefore come out “short”

Its a printer’s job to trim the creep! Now, my guess is they don’t have an offline saddlestiching unit. They’re simply having their digital press do the binding and then putting them into the box. Without a saddlesticher that can trim all three sides of your book it becomes hours of hand trimming 4 or 5 book at a time.

Inform your company you need a printer that’s either willing to put in the time, or has better equipment.

Thanks for the responses. It’s not creep. It starts on the first page and the pages are the same distance throughout. I’ve been doing magazines for over 10 years, easily have over 100 issues under my belt, and have never had this issue. I think it’s equipment failure/incompetence. We were unable to recall the job because by the time we got them, over 90,000 had been mailed out from their mailing house.

We are very specific that the cover has to be No. 2, 100 lb. Sterling Ultra gloss web text and the interior has to be No. 3, 60 lb. Verso Influence Soft-gloss web text. They even have to send us samples to prove it before they’re allowed to move forward in the bid process. We also fly to wherever the plant is and do a press check but we aren’t there for the binding. We had some other problems with this issue as well. For example, the cover came back gritty instead of a smooth glossy feel. I have a feeling they were bs’ing me but wanted to be sure I wasn’t missing some new print issue. Here’s a scan I did of a portion of the cover. That little gray box with the red stroke is the first page…the table of contents.

Edit: I suppose my scan is big so you have to click on it to see the gray box I mentioned!

I’ve seen other magazines with that exact problem, and it’s clearly a trimming error. Even if there was such a thing as “page growth,” there’s no way it could be that big without all of us already knowing about it, and without the industry having devised a fix or preventive measure decades ago.

I’d revoke their eligibility to bid in the future.

Thanks HotButton. I want to revoke their eligibility and am pretty sure this is grounds for it. We’ll be going out to bid soon for the next issue so I wanted to be sure there wasn’t something new I’m supposed to be doing on my end. We put a lot of effort into the magazine. After well-lit, custom, relevant and well thought out photoshoots and meticulously written articles, it’s frustrating to have it come back with this sort of error that’s apparently out of my control.

This was the explanation they emailed to us:

“The job was printed on a heat-set press. The printing process adds moisture and the oven takes moisture out of the stock which causes the paper to shrink in width. After bound, the paper gradually absorbs moisture causing the text pages to grow out after the book is trimmed, which is called “Web Growth.” That is why the interior pages have grown out past the sheetfed printed cover. The sample provided as color bar showing on the inside. This is a saddle machine issue in the application of the cover.”

I think her response is bs.

I agree. Even if that much growth could be explained credibly, it’s still a quality control issue that’s theirs to solve or prevent before it ruins your whole run. Whatever caused it, they failed to produce your job to-spec.

Actually, I don’t think it is BS, but I think them using it as an excuse is BS.

I didn’t realize they printed the inside on a web heat press and the cover on a sheetfed press. They’re very different printing processes where heat and humidity affect the stock differently. There also might have been an issue where either the inside or cover paper stock had recently arrived from the supplier and hadn’t yet adjusted to the local humidity levels before it was printed and trimmed.

Even if this is the explanation, it doesn’t excuse it. The printer should have compensated for all of this, but they didn’t. I’d be looking for a new printer.

Just found this: http://blog.johnroberts.com/the-web-creep-phenomenon

Incredible! Who’d have thought it. One learns something new every day.

I agree, if it’s an issue and a known issue, they should have trimmed the cover 2mm larger so that it would compensate. Ideally, the cover and guts should match but a cover that is a fraction too large is better than a cover that is too small IMHO.

I think her using it as an excuse is bs. They’ve printed a previous issue for us at a different plant and it turned out great. I suppose all I can do is use it to disqualify them from winning the next bid and let the next printer know this was a problem for us. I’m glad to know fault doesn’t lie on my shoulders. They dismissed it as no big deal when it’s a very big deal for me. I put a lot of work into this magazine to represent us well.

and let the next printer know this was a problem for us.

Yes this! It’s the best thing you can do for your next printer. When I worked in print, I hated when a known problem was shared after the second time.

Great link from John Roberts printing. I love JR and have used them. They had the answer to the problem, the papers need to both be “conditioned” before they are trimmed. That is something the printer is aware of and in control of.

What did you end up with? Did you reprint or trim again?