Hey everybody.

I’m not actually new here, but it’s been awhile, SO.

I’ve been a freelance/in-house illustrator and designer for about 10+ years and recently acquired my first out-of-state client. It started off easy enough with a fun little brochure, but the second project is apparently a wrap for a 120’ section of construction fencing around their new building site (that I will never see), and frankly, I’m not even sure where to start. Has anyone done a project like this, and could you share some tips on file set-up, scale and any other surprises one might encounter? Postcards, t-shirts and websites I understand, but this is a new adventure.

Thanks!

This is considered wide format printing.

Fence hordings are usually done on a mesh material, but might also be vinyl with wind cuts (not as common as no one wants their fence to blow down.)

At 120’ long, working in 1:10 scale is probably easiest (you can work in inches and just move the decimal over 1 place.)

Is it copy? Or imagery? Billboard resolutions apply to imagery so anywhere from 30-50ppi at full size works (working in 1:10, that’s 300-500ppi.)

There’s a lot more to it, so it would be best to be able to get the specs from the printer doing the printing. See if your client can get you the file submission specs too. A lot of wide format printers want native files, especially when scaling is involved, not PDFs.

I also expect since 120’ approaches an entire roll of media, you may be looking at doing this in stitched or perimeter grommeted sections. Some fences are done by sections between uprights. You may need to know the width of the sections to avoid losing any text in the gaps between grommetted panels.

Do not forget your bleeds. They will be larger than you think. If paneled, 2" all around. If it’s a full run of 120’ I’d give it an extra 6" each end (12 total) that will likely be cut off.

Good luck.

Awesome. Thanks so much. The client hasn’t picked out their printer yet, so I hope that info will come quickly. I appreciate having some idea of what to ask them, although I assume they’ll probably be used to working with people who need a small manual to start with.

Usually there will be just a single web-page spec sheet.

Sometimes it’s up to the designer and client whether or not to break up the piece into sections and where.

I’ve seen these done as multiple panels between the uprights with a different message on each.

This is not the place to be using small imagery. Think of it as a billboard.

Speaking of that, you might want to check into the local sign ordinances. Or at least put in the caveat that you aren’t responsible for pulling local permits for “signage.” Once you start putting words or advertising on there, the local zoning board will (most likely) get involved.

I saw some guys putting hardware store tarps on fencing one day. Few days later we had 35mph wind gusts and that tarp, the fence it was tied to and the cement blocks the posts were standing in, were blown out into the street. They cut some huge windslits in it, which kinda defeated the view-blocking idea.

That’s a good point re:zoning. They do want to have words and imagery, so I’ll ask them about it. They’re in a neighborhood in Portland, and I believe they want to turn the wrap into reusable grocery bags once the building is finished, so that may help determine the kind of material we use (although I don’t know the specifics on that either). I’ve only done digital billboards in the past.

For proofing and mockups I get them to take MANY photos AND measurements of the location and of the fencing if it’s there already. It’s helpful for all to view “in place” before you go ahead and print anything. I agree the mesh is likely the best, but remember when using the mesh all colors tend to look a bit more washed out because of the holes in the material.

It’s really important that before you start designing you chat with the printer… they will want specific file setups that will save you design/refining time for file prep. If you client hasn’t picked them yet, be sure to add that extra design time into your quote. It also depends on how they will install… maybe one long 120’ piece will be challenging/heavy and they suggest working in panels instead… If it’s fencing being installed for a construction site, likely it’s in panels anyhow. Also if your software will let you work at 100% then do it… it eliminates resizing surprises.

Also I’ve found that 72dpi images for hoarding look good and are easier to work with BUT it depends on what the printer suggests (one more reason to chat first) AND how far away the signage will be viewed.

Also think about the audience-- they should be able to get the “message” within a few seconds if they are driving by so keeping it simple is a good rule to follow. Might be helpful to Google fence mesh signs to get inspired.

You guys are amazing.

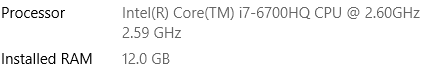

My PC laptop is good, but probably not 100% good. lol. I admit that this is something that concerns me quite a bit too. I hope it’s up to the task.

But you mentioned the quote, and I’ll need some advice in this area too. I realize that the design itself will be be simple enough and the hardest part is just the setup, so I probably wouldn’t charge hourly. Is there a reasonable ballpark flat rate for this so I don’t destroy other designers in that area? I’m not familiar with this company’s budget yet, but they appear to be a larger, well-funded non-profit. That being said, I imagine they’re only using me (here in Kansas) because designers in Portland are 10x more $$$. I might go ask some local AIGA people for local rates, but keeping the price fair in that area matters to me.

I’d ask them their budget upfront, or at least what they expect this project to cost in total. If they ask you for a quote, I would totally do it hourly. You’re going to be spending time with them to get dimensions and work with the printer and that may take a little time. Also if you’re responsible for researching reusable material, that is time too. Before you can even grasp this project, you’ll have to find out what you’re responsible for… just the design or the design, printing, and installation.

If you are doing individual sections, definitely work at full scale.

I’m not particularly fond of mesh for anything.Sunlight gets behind it and blows right thru the image, kinda like the stage effect of using a theatrical sharkstooth scrim, when backlit you can see behind it. When frontlit the imagery is visible.

http://dictionary.tdf.org/scrim/

It’s actually kind of amazing graphic designers aren’t aware of this. I get requests for window graphics on mesh all the time. Can’t see the image when daylight shines in and at night from outside, you can see right in (like the windows perf on buses at night)… Same goes for a lot of “frontlit” fabrics, which have various degrees of pinholing, whereas backlit fabrics are made to be backlit and give a vivid image.

But I digress.

There are various mesh blow-thru weaves as well, everything from Textilene and Speaker mesh (about 70% blow-thru) to Ultramesh Supreme which is only about 25% blow thru (not something I’d recommended for fences.)The tighter the weave, the better the image. But also the more chance of your fence blowing over. The printer should have something they recommend.

On the subject of reusable material, now you are probably looking at a scrimmed vinyl, not a mesh. And it’s really tough to find places to take it unless the printer happens to have a take-back program (notice I did not say buy-back. You may have to pay them to take it back.) There are places that do convert old vinyl billboards into up-cycled objects such as handbags, but again, very hard to find and there is far more supply than they demand. Wind slits are only going to make that more difficult. I commend the thought though.

Beware the “eco” banner products. Again, a good thought but be sure the by-product doesn’t include miniscule bits of plastic that disperse into the environment once the bio-binder breaks down…I don’t have any recent research on which ones are good (they all pretty much suck for image quality, IMHO,) I just remember that comment from a speaker on recycleables at an SGIA seminar several years back.

Just for the record, here are my system specs, with CC19.

Windows 10

331 GB storage left

Think the old girl will be able to handle it? Or will I need to snag an external?

Those specs are fine, though not quite sure how you have 12 gigs of ram installed (unless you computer handles unmatched ram sticks. I guess you could have them paired as two 4s and two 2s…)

You are not doing these at 300ppi at this size. You are doing them anywhere from 30-80ppi. I’d highly suggest using InDesign just for processing time, Illustrator is a processor killer when using large placed imagery (placed, never embedded.) Illustrator also has long redraws on any effects used. And InDesign handles color better in general…but you should check that the printer accepts InD files. Most do ,but you never know when you’ll hit a holdout (I’d run in the other direction, but if your client is choosing the printer, you may not have a choice.)

Remember when working in scale you have to multiply the resolution.

For instance if you are working on a 50ppi image at full scale, when working at half scale the image has to be 100ppi. If working in 1:10 scale it has to be 500ppi. You can’t save “processor time” by working in scale. The image information has to be there and the image will be as large at 10% as it would be at 100%. If it isn’t, you are doing it wrong.