It seems you copied what you wrote from this website: How do I check and change the ink coverage? | PrintSimple

Anyway, I agree with the others; total ink coverage is not typically something to worry about (usually). However, familiarizing oneself with ink coverage issues is a good idea. The more a designer knows about printing, the better off that designer will be in making decisions that take printing capabilities and limitations into consideration.

I’ve known designers who naively specified rich black as 100% of all the process colors, which is the recipe for a muddy mess and leaves the printer in the position of deciding what that rich black should be. In addition, you can’t count on printers necessarily fixing things. Gang printers, for example, don’t get too involved in ensuring that all the various colors from each job on the press are ideally separated.

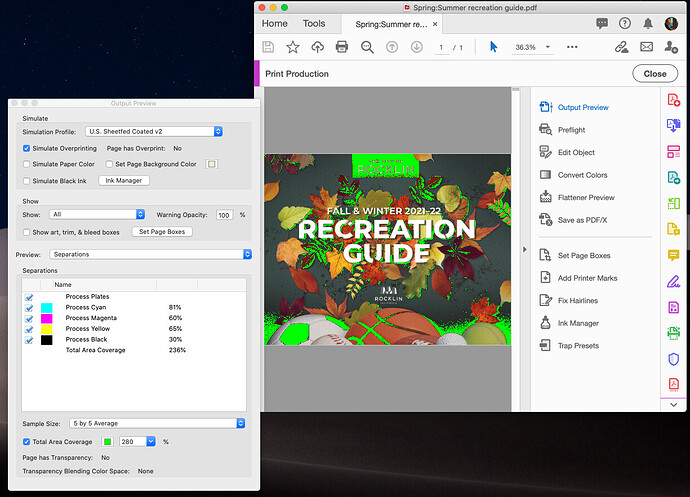

Acrobat lets designers check and change total ink coverage in PDFs. Acrobat has a Print Production button that heads to an area where there’s an Output Preview button.

The Acrobat screen capture attachment shows the cover of an InDesign booklet I recently completed that shows all the areas in bright green where the ink coverage exceeds 280%.

As mentioned, the printer would almost certainly scale this back for me, but knowing some areas were too dark, allowed me to cut back some of the denser areas without needing to hand off the problem for the printer to fix and hoping that it looks right.

Acrobat, by the way, also provides a means to readjust those separation densities across the entire PDF before sending it off to a printer. Whether or not to do this, of course, depends on the job, knowing the printer’s recommended maximum TIC, and whether or not it’s an appropriate thing to do for the job at hand.

As I mentioned earlier, the on-demand book publisher, IngramSpark, specifically recommends sending files with a maximum TIC of (can’t remember for sure) around 240%. Having printers specifically request this is a rarity, but it’s a good thing for every designer to know about.