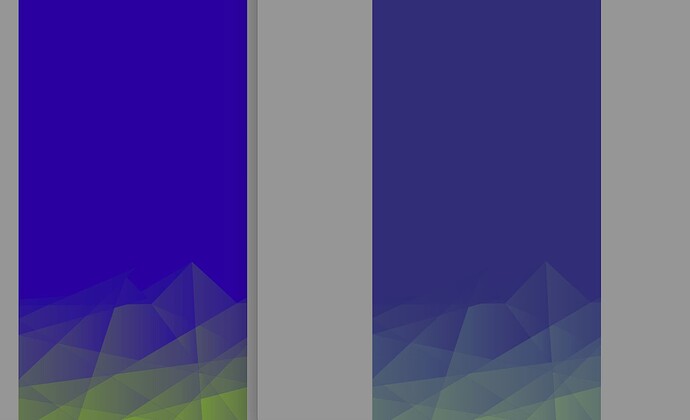

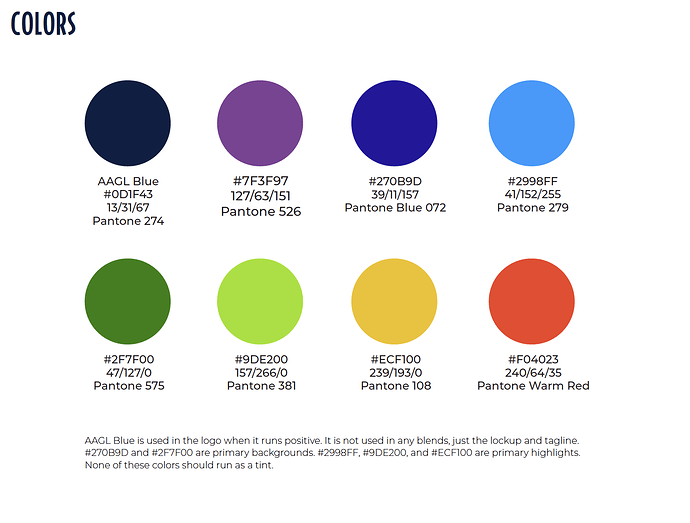

I’m creating a series of banners that have a strict branding guidelines for an event. As you can see the background of the banner is so much brighter as a RGB file than when it is converted to CMYK for print. This is to be expected but I made sure my client was aware of this; they do want to match the RGB colors as closely as possible and instructed to use 072C as the Pantone color for the blue. I also suggested Pantones as a better option to more closely match the brand colors and banner template. I am designing this file in Illustrator and all parts of it are vector (except for an images I need to add into the file which will obviously stay CMYK).

I also need to make sure the printer they are using is capable of creating Pantones and if my client is ok with the increase in cost.

I don’t have as much experience in printing Pantones; only basic knowledge - so here are just a few questions I have if anyone has advice:

-

If the printer can’t afford Pantones, is there any way to fiddle with the colors in CMYK to retain some of the brightness? I read a color burn might help but I’m assuming that causes unpredictable results when printing.

-

If using the Pantones, the files should still be set in CMYK, right? I ask because the brightness of the Pantone goes right back to that dull conversion and I’m worried that’s how it will print.

-

Now that my file is in CMYK, I feel like I don’t have an accurate view of how my screen is displaying the true values of the Pantones vs the CMYK because the entire file looks dull. This worries me when I start to add elements that will be CMYK onto the Pantone background as I have no idea what the final result in print will actually look like. Am I right in thinking this?

-

I don’t know much about Pantones but 072C means on coated paper, right? I have no idea what the stock for retractable banners are and if it is typically coated. Is this another problem I will run into?