I’m a bit familiar with the application of this pallet rack, so I’ll try to briefly explain what it’s about:

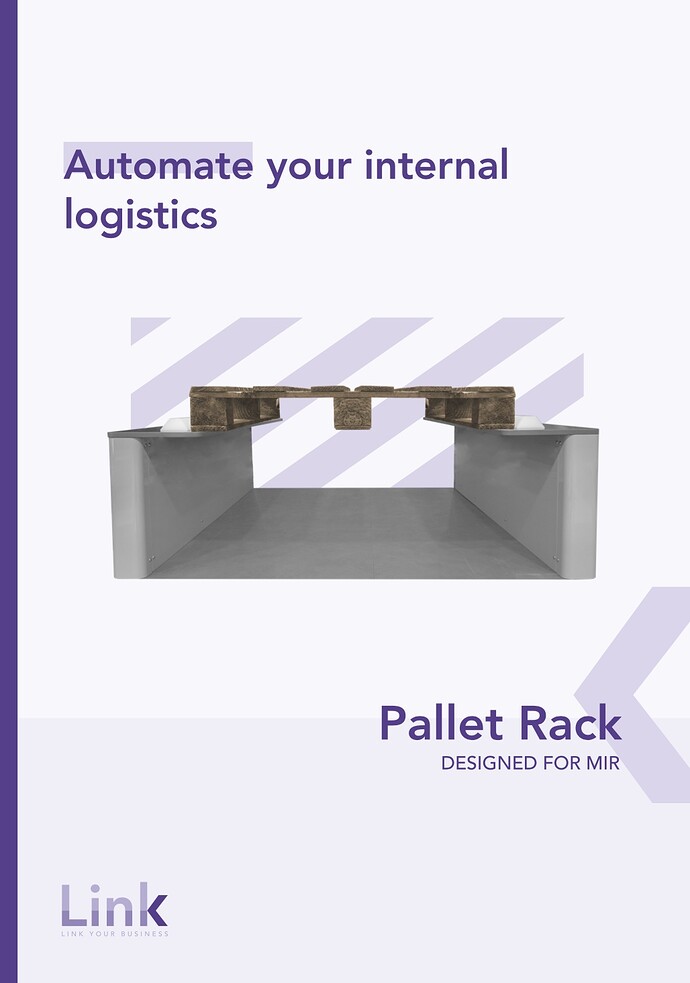

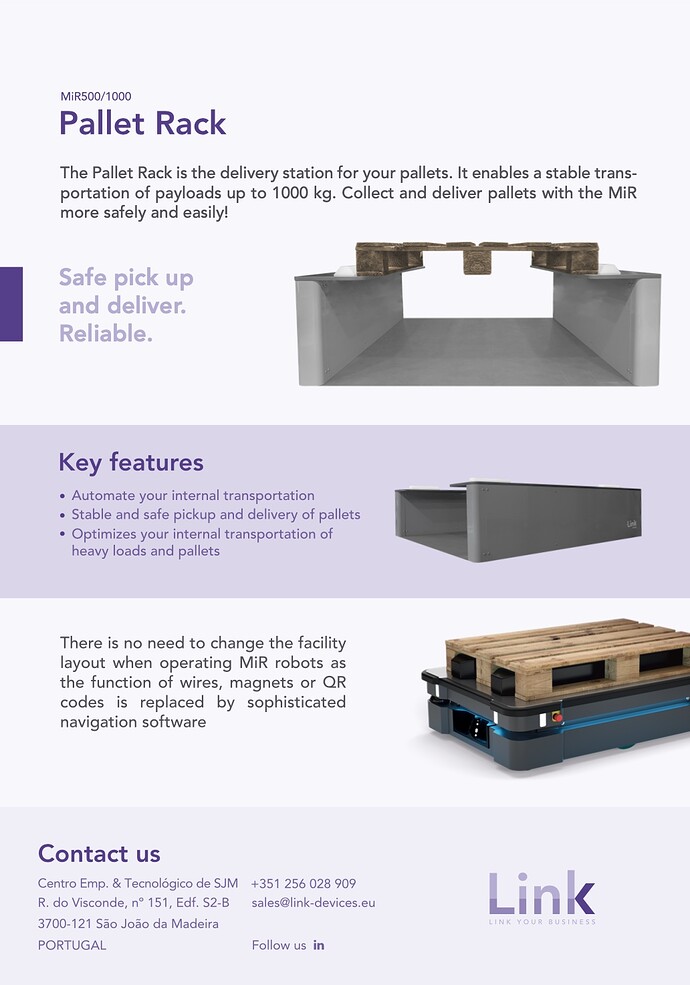

In order to transport a pallet, an AGV needs to be able to get underneath it. The purpose of the pallet rack is to hold up a pallet high enough for the AGV to drive under it and then push the pallet up with the AGV’s lifting table to take the weight of the goods and carry it away to a different rack, where they can then be picked up by a forklift, for example, in order to load them into a truck.

Anyway, to get to @RubenPinho 's brochure design, it’s clear that the application I just described is not immediately clear to everybody. It’s actually a quite simple process, that could easily be shown in an illustration. If the application not clear to the people here, it might also not be immediately clear to some of the customers you want to attract with your leaflet.

Another point is that you fail to highlight the specifications of your rack sufficiently, in my opinion.

Let’s start with the load capacity. You state that the load capacity is one tonne, but that’s about it. I assume that corresponds with the load capacity of some of MiR’s models, so why don’t you state them? As a buyer I don’t want to have to cross-check if you’re load capacity is sufficient for the AGVs I got. Moreover, if your rack is “overengineered” and can hold more than it needs to, it would give me additional peace of mind.

Next is dimensions. I understand that you don’t want to give too much away so that others can’t just rebuild your product, which is effectively just a metal box, but you need to provide some dimensions to your prospects. In warehouses every mm counts as valuable real estate and you need tell them how big your rack is. It’s also something that you want architects and consultants to specify as per your dimensions, so make sure you communicate them.

Last but not least, some practical bits. How is the rack mounted on the floor (ideally without any ground work)? Does it have fixings for charging contacts (since the loading/unloading operations are the ideal point of time for a quick opportunity charge of the AGVs)? Is it suitable for corrosive environments (e.g. many F&B warehouses)?

I could go on, but I hope this helps you already.